Build your own dog house

This doghouse is designed with the beginner in mind. It might even be a good project to involve the kids. The entire project requires only one sheet of plywood, two 2"x4"s and one 2"x2". All of these materials are available at your local hardware store.

Supplies:

1PC - 4'x8' Exterior Grade Plywood Sheathing (5/8" thick)

2PC - 2"x4"x8' Pressure Treated

1PC - 2"x2"x8' Untreated

1 Box - 16d nails

1 Box - 1-5/8" Galvanized Deck Screws

1 Quart - Exterior Grade Paint

Construction

This doghouse plan is very easy to build and requires a minimum number

of tools. Most beginners should be able to finish the project in a

day. The only tools required are:

· Tape measure

· Circular saw or table saw

· Drill - with drill bit and screw driver bit

· Spade Bit (3/4" or larger)

· Hammer

· Paint Brush

· Pencil

· Safety Glasses

· Carpenters Square

There are a couple of important considerations when building and designing a doghouse. Please keep these in mind if you plan to modify the plans to fit your needs.

1. Don't use pressure treated wood on any parts the dog may chew.

2. The doghouse should be raised from the ground to keep out moisture and help insulate the dog from the cold.

3. The doghouse should be large enough for the dog to comfortably turn around but small enough to retain the dog's body heat.

Shingles

We decided to cover the roof of this doghouse with cedar shingles. A

simpler, less expensive option is to paint the top of the doghouse or

use asphalt shingles.

Plywood

The doghouse should be built from an exterior grade plywood. Most of

the plywood you will find at your local hardware store is not exterior

grade. Exterior grade plywoods have special glues that prevent the

layers from coming apart when they get wet. Do not use Pressure

Treated (PT) plywood, it contains preservatives that can be toxic to

your dog. The best

material to use is an exterior plywood sheathing. This wood is designed

to be used on the outside of a home. It has a "rough cut"

surface with grooves cut into the surface for decoration. We used

exterior grade sheathing that has the grooves 4" apart. You can

also get the plywood with grooves 6" apart.

The edges of exterior grade sheathing are "tongue-n-groove". This means that there is a little lip on one edge that fits in the groove on the opposite side of an adjoining piece of plywood. We do not need these parts and will cut them off of the plywood sheet. You might want to ask a salesperson at the hardware store to do this for you before you leave. All plywood parts of the doghouse are assembled using 1-5/8" decking screws.

Foundation

Because the foundation of the doghouse will sit on the ground we used

pressure treated 2"x4"s. It is unlikely that the dog will

chew these boards however if you think your dog may gnaw on them you

may want to use untreated wood and paint it. We also drilled 1"

holes in all sides of the base to allow ground moisture to evaporate

and prevent rotting. The foundation is nailed together using 16d

nails.

Roof

The roof to this doghouse is designed to be removable. This will allow

for easy cleaning of the interior areas.

Front Porch

The front porch is a nice touch to this design. Our dogs love to hang

out on the porch in the shade. If you prefer you can easily leave this

part off.

Porch Posts

The porch posts are made from untreated 2"x2"s.

Step 1 - Print Cut Lists

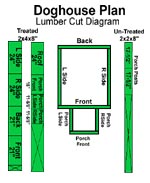

Click on the images below and print the enlarge cut lists.

Step 2 - Layout the Parts

Before making the first cut you should lay out all of the parts. This

means measuring and marking all of the parts onto the plywood and 2x

lumber. Use a carpenters square to ensure straight perpendicular

lines. It is also a good idea to label each part for identification

later.

Step 3 - Cut the Parts

After you lay out all of the parts cut them out with a saw. Be careful

not to cut into any other parts and try to make your cuts as straight

as possible. Trim off the tongue and grooves before cutting the

parts out.

TIP - If you don't make a cut perfectly straight don't worry.

You can probably fill in the gap with caulking compound before

applying the final paint job.

Step 4 - Assemble the Parts

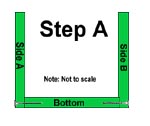

Step A - Place the "BOTTOM" on your workbench and attach "SIDE A" and "SIDE B" to the base using 1-5/8" galvanized deck screws. The screws should go through the "SIDE PIECES" into the "BOTTOM".

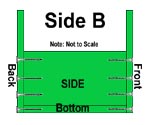

Step B - Attach the "FRONT" and "BACK" parts to the "BOTTOM" and "SIDE PIECES".

Step C - Attach "ROOF A" and "ROOF B" to the "ROOF 2x4"

TIP - The "ROOF 2x4" should be centered between the roof sections.

Step D - We are now going to assemble the 2x4 base. Use 16d nails and assemble the 2x4 parts as seen in the "Lumber Cut Diagram". Pay special attention to overlapping the lumber as seen in the diagram. After you assemble the base, use a 3/4" (or larger) spade bit to drill two holes in both the "R SIDE" and "L SIDE" of the base to allow moisture to escape.

Step E - Attach the body to the base using six 1-5/8" galvanized deck screws. Screw through the "BOTTOM" into the base making sure to sink the screws slightly into the wood to protect your dog from sharp edges.

Step F - Attach the "PORCH BOTTOM" to the base using six 1-5/8" galvanized deck screws making sure to sink the screws slightly into the wood.

Step G - Attach "PORCH ROOF SIDE A" and "PORCH ROOF SIDE B" to the "PORCH ROOF". Screw through the roof and into the side pieces.

Step H - Attach the "PORCH FASCIA" to the front of the "PORCH ROOF"

Step I - Attach the "PORCH POSTS" to the "PORCH ROOF"

Step J - Attach the "PORCH ROOF" to the body of the doghouse by screwing into the roof and roof sides from the inside of the doghouse. Also screw through the "PORCH BOTTOM" into the "PORCH POSTS" to secure them in place.

Step K - Paint the doghouse using an exterior grade paint.

Note: The roof is not attached to the doghouse body. It sits on the body and is removable for cleaning.Congratulations! Your dog now has a new home. We hope you enjoyed the plans. Please let us know how the project went for you. We'd love to see a picture of how you decorated the house! (see below)

Visitor Pictures:

Content provided by: WoodZone.com for educational purposes only.